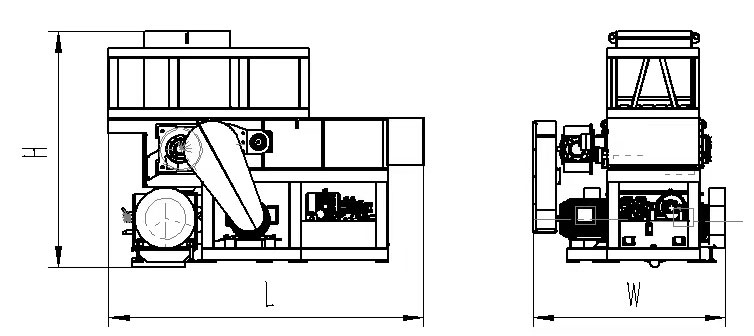

Shredder&Crusher all-in-one machine

Model & Parameters

|

Model |

JRSC2260 |

JRSC4060 |

JRSC4080 |

JRSC40100 |

|

L(mm) |

1870 |

2270 |

2770 |

2970 |

|

W(mm) |

1420 |

1720 |

1970 |

2170 |

|

H(mm) |

1800 |

2200 |

2200 |

2200 |

|

Shredder Cylinder Stroke (mm) |

600 |

700 |

850 |

950 |

|

Shredder Rotor Diameter (mm) |

Ф270 |

Ф400 |

Ф400 |

Ф400 |

|

Shredder Main Shaft Speed (r/min) |

83 |

83 |

83 |

83 |

|

Shredder Screen Mesh (mm) |

Ф40 |

Ф40 |

Ф40 |

Ф40 |

|

Shredder Rotor Blades (PCS) |

26 |

34 |

46 |

58 |

|

Shredder Stator Blades (PCS) |

1 |

2 |

2 |

2 |

|

Shredder Main Motor Power (KW) |

22 |

30 |

37 |

45 |

|

Shredder Hydraulic Motor Power (KW) |

3 |

3 |

3 |

3 |

|

Crusher Rotor Diameter(mm) |

Ф300 |

Ф400 |

Ф400 |

Ф400 |

|

Crusher Rotor Blades (PCS) |

18 |

18 |

24 |

30 |

|

Crusher Stator Blades (PCS) |

2 |

2 |

4 |

4 |

|

Crusher Screen Mesh (mm) |

4-12 |

4-12 |

4-12 |

4-12 |

|

Crusher Motor Power (KW) |

15 |

22 |

30 |

37 |

|

Particle Size after Crushing (mm) |

Ф5-12 |

Ф5-12 |

Ф5-12 |

Ф5-12 |

|

Air Blower Motor Power (KW) |

2.2 |

3 |

4 |

5.5 |

|

Weight (kg) |

2800 |

3600 |

4600 |

5500 |

Write your message here and send it to us